Precise pipeline sizing

for industrial pipe manufacturing

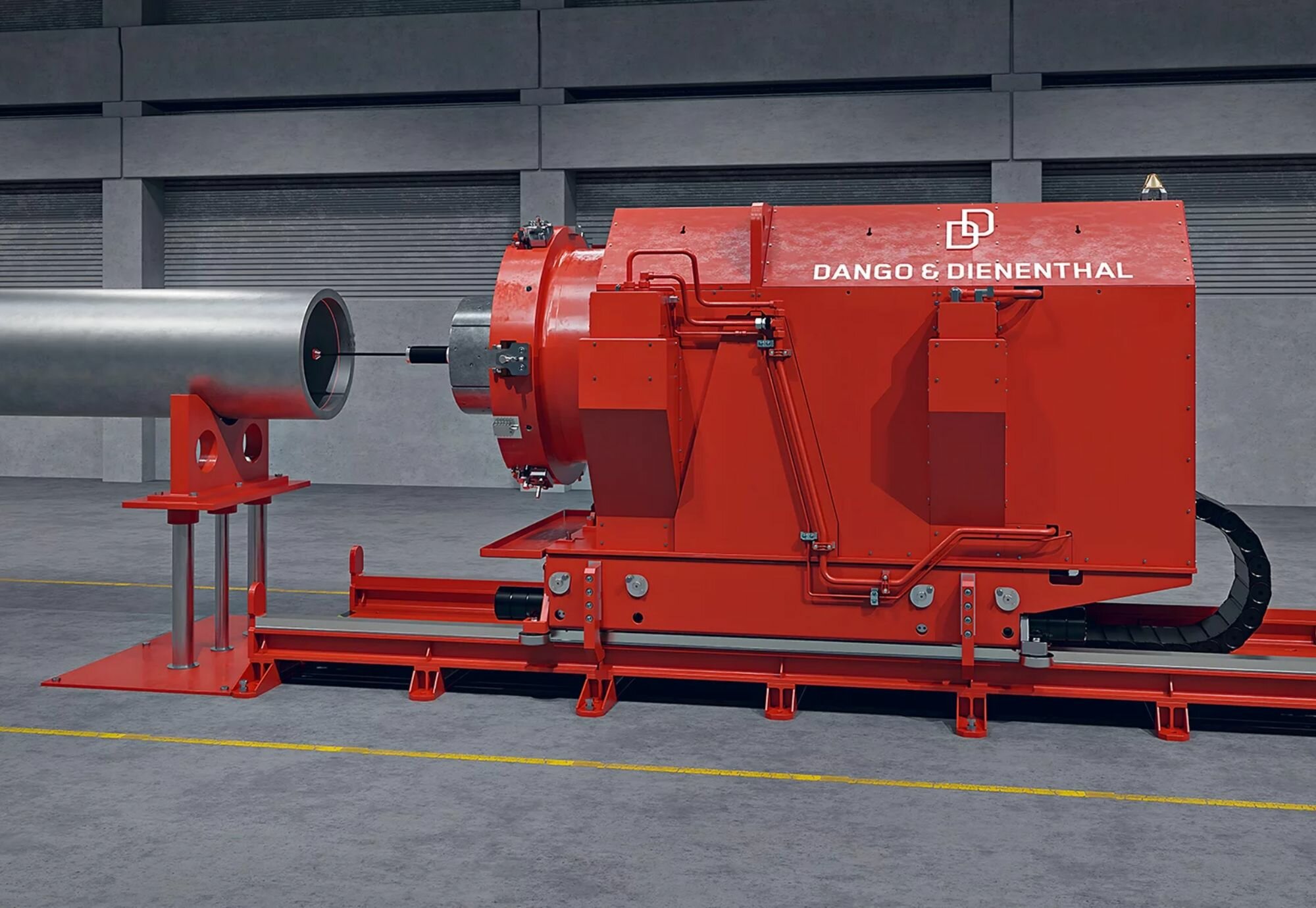

Pipe Sizer

Increasing efficiency for your pipe sizing in large pipe manufacturing

Our Pipe Sizer offers precise pipe calibration for pipe manufacturers with the highest demands in industrial pipe manufacturing processes. Whether for thick-walled large pipes or special geometries: We supply the right pipe processing machine for your efficient pipe production with maximum dimensional accuracy.

Up to 300 % more output with

same fixed costs

Speed up your pipe manufacturing by eliminating unnecessary intermediate steps. Significantly increase your productivity with integrated measuring and calibration technology.

Dimensionally accurate pipes with optimum roundness (≤ 0.08 in ovality)

Ensure maximum accuracy of fit for welding processes. Error-free pipe calibration reduces rejects and increases the quality of your production.

Less rework,

more planning reliability

Automated processes guarantee consistent pipe quality with minimal reworking for stable production processes and reliable delivery dates.

Rapid amortization

- ROI in just 3 months

Reduced crane times, shorter project lead times and higher production speed lead to profitability from the very first large order.

Pipe Sizer

In the application

Project details/ scope of delivery

- Machine type PST 1300 PE EX with integrated 360° laser measuring system for measuring and spot straightening pipe ends (incl. additional expander function)

- Double system with two opposing PIPE SIZER units

- System software (PLC software and DDPST software specially tailored to the pipe industry by DANGO & DIENENTHAL)

- Programming of the customer's pipe routing and positioning (automatic center point correction)

- A stationary hydraulic compact unit for both machine units

- Tools for flexible use with pipe diameters (iØ) from 10.87 – 40 in

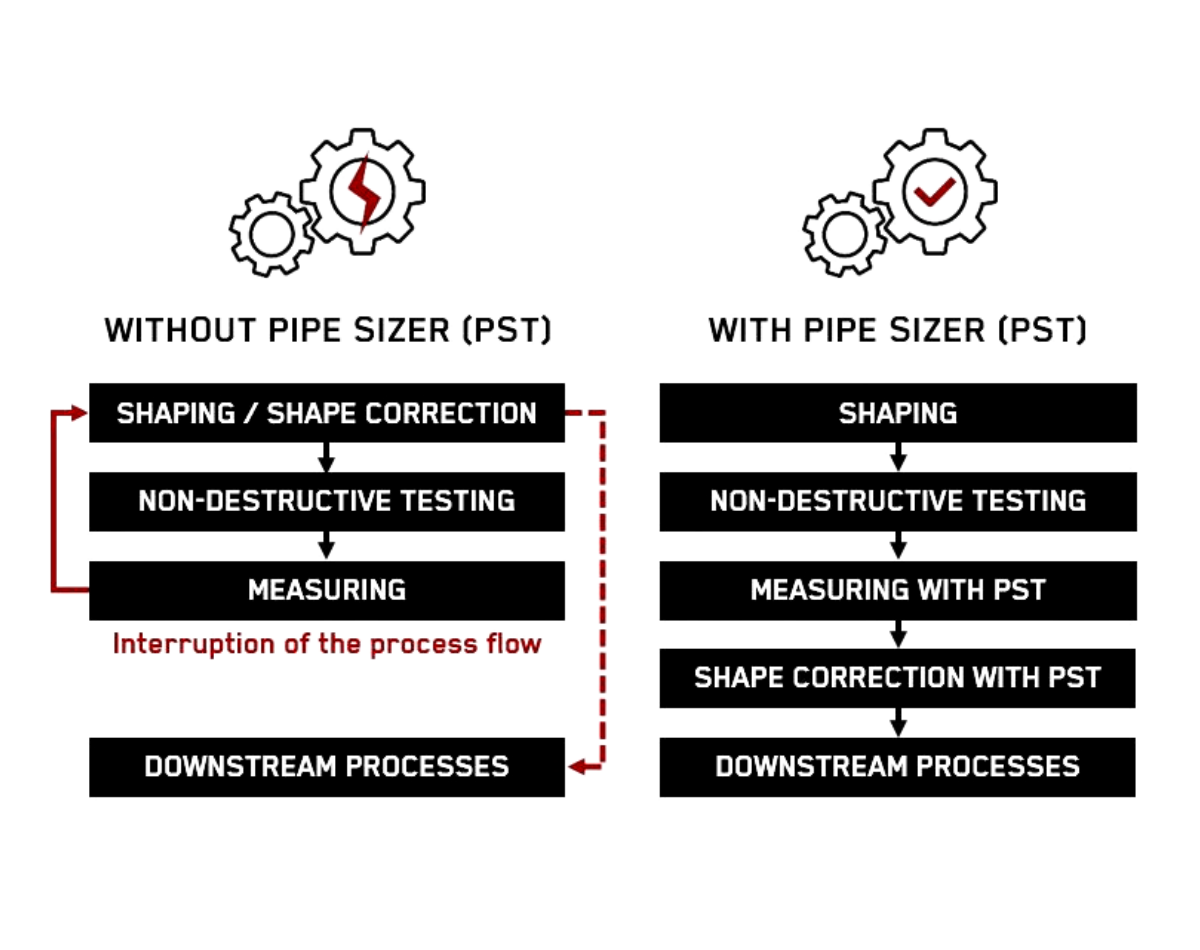

Without PIPE SIZER, forming, testing, measurement and correction take place at separate stations. Deformations require returns. The process flow is interrupted, crane times increase and production time is lost.

With the PIPE SIZER, measurement, evaluation and correction are carried out in one system without return, machine changes or set-up times.

You save time: instead of 2.5 to 3 hours, you only need 15 minutes to reliably achieve the target ovality.

EFFICIENT PIPE CALIBRATION WITHOUT INTERRUPTING THE PROCESS

In industrial pipe manufacturing processes, deformations that occur after testing often result in returns and lost time. The PST series solves this problem by combining pipe calibration, measurement and correctionin one system without the need for a return or machine change.

Pipe manufacturers benefit from shorter throughput times, consistent quality and a stable process. With the PIPE SIZER, you can achieve the target ovality in just 15 minutes for economical, precise and automated pipe processing.

Find out more about the Pipe Sizer