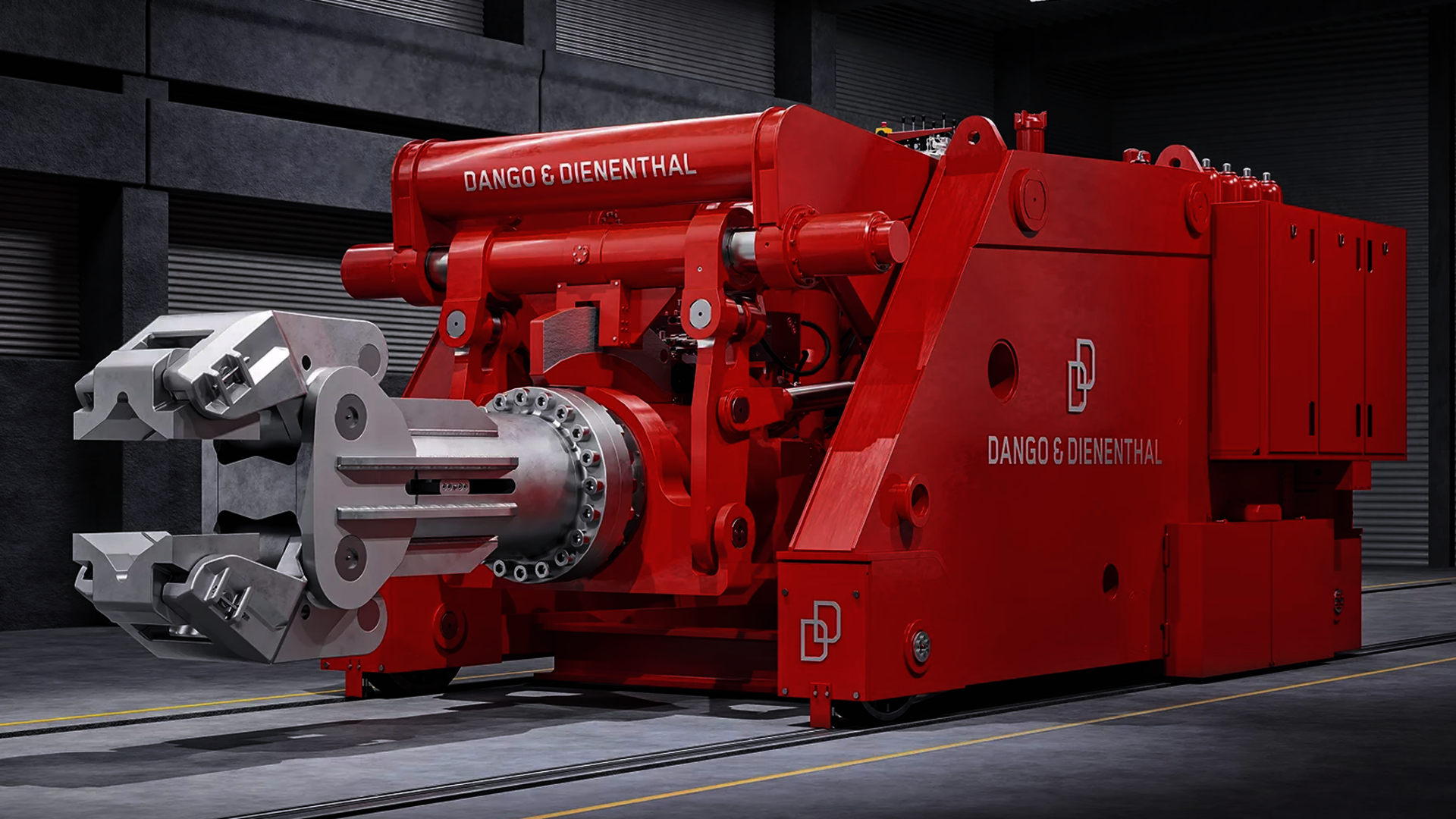

SSM SERIES

Rail-bound forging manipulators

MAXIMUM CONTROL IN THE FORGING PROCESS

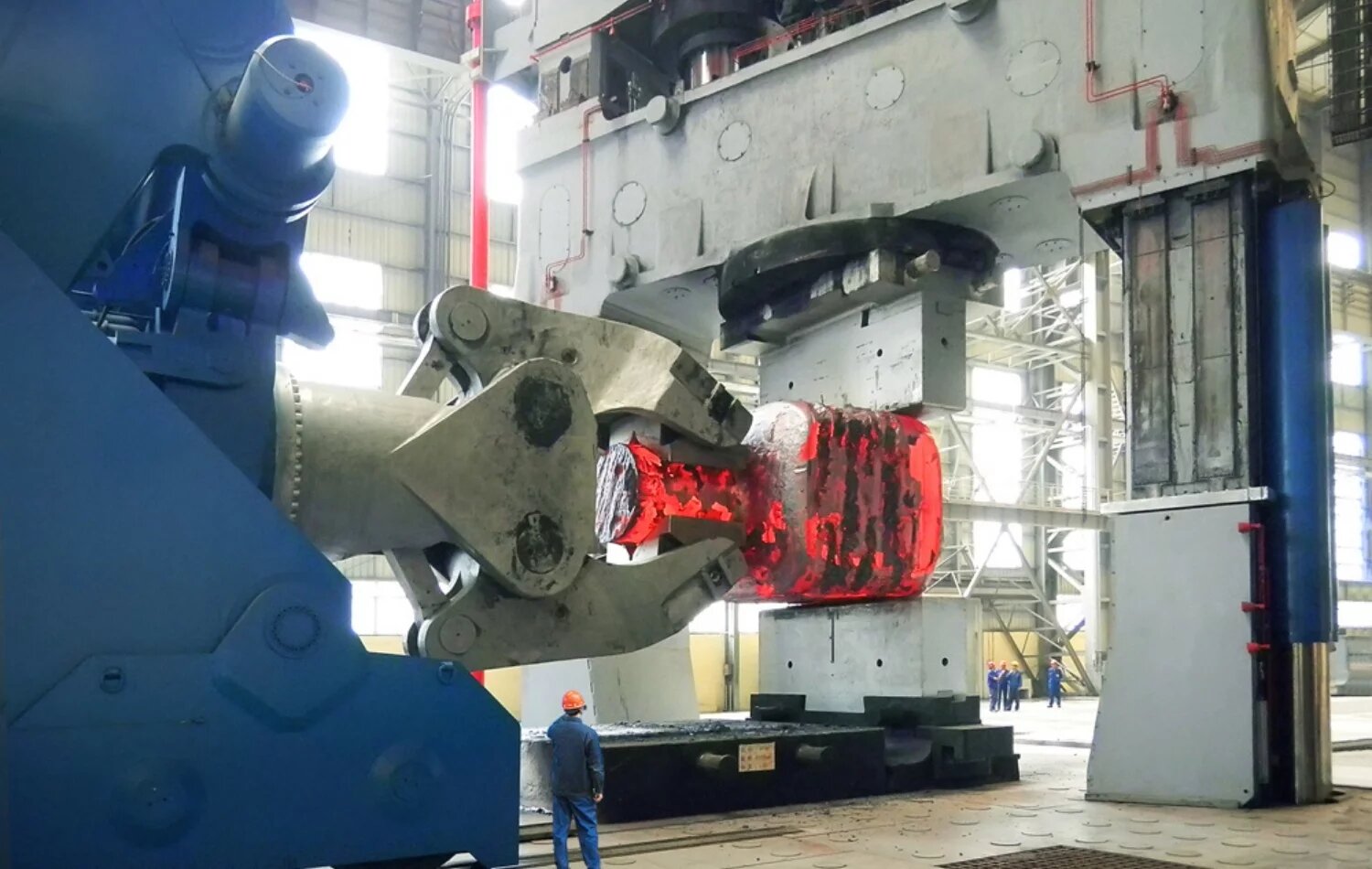

The rail-mounted forging manipulators from

DANGO & DIENENTHAL have been specially developed for the extreme requirements of open-die forging.

With forging machines that combine precise motion control, powerful handling capabilities, and seamless integration into digital manufacturing processes, you benefit from exact positioning and safe manipulation of the heaviest workpieces – even in the most demanding applications such as the aerospace, defense, and rail industries.

Worldwide, more than 50 DANGO & DIENENTHAL large manipulators with forces exceeding 800 kN are already in operation – ensuring near-net-shape forging results, minimal allowances, and maximum process reliability in production.

With the design developed according to the POSISTABIL principle, you benefit from exceptionally stable workpiece guidance, with the forging manipulator holding the workpiece securely in all directions throughout the entire forging process. The tong carrier moves only when required by the process – enabling you to achieve highest dimensional accuracy, reproducible results, and premium-quality forged products.

Construction and function

of the forging manipulators

MORE EFFICIENCY AND PRECISION

The hydraulic system of the rail-mounted forging manipulators is designed for maximum precision and efficiency. All main movements are hydraulically driven, allowing you to move the chassis and tongs simultaneously for shorter cycle times in the forging industry.

Travel, lift and rotary drive

Depending on the machine size of the forging manipulator, you can achieve a positioning accuracy of the travel drive of ± 1.5 to 4 mm thanks to the backlash-free, tensioned rack and pinion drive.

The zero-cut valve technology ensures a fast response of the hydraulic system, allowing travel, lifting, and rotation movements to be carried out more quickly and directly. Thanks to the patented automatic calibration, valve wear is automatically compensated, preventing any drifting of the axes.

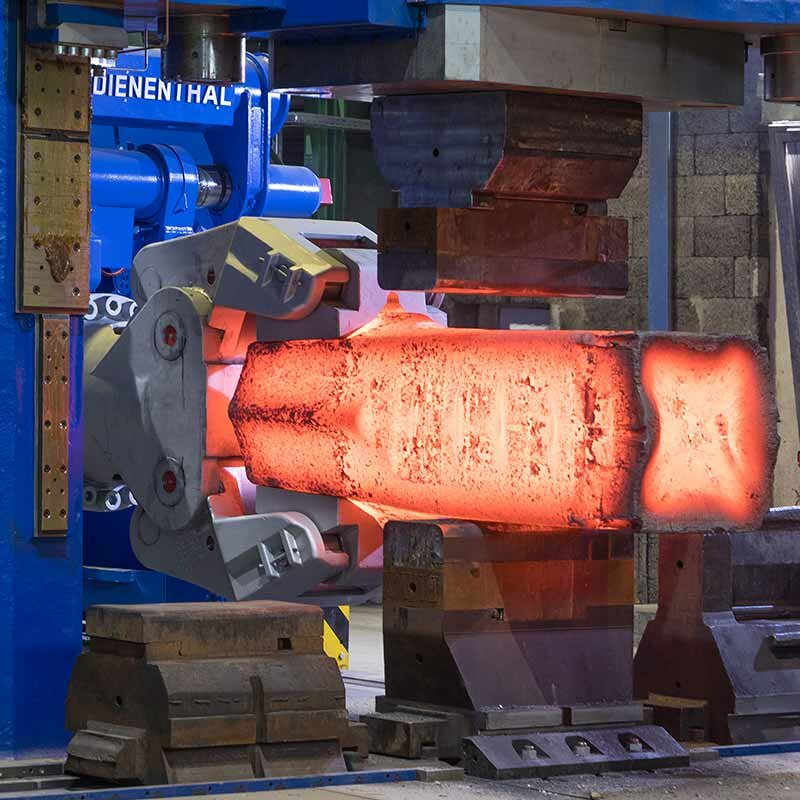

Tong drive

The tongs are controlled without delay via its own hydraulic circuit. The integrated “height reset” system automatically adjusts the tong height to match the press stroke – ensuring consistently uniform forging results throughout the entire process.

Energy-Recovery-System (ERS)

The optional Energy Recovery System (ERS) feeds braking energy back into the hydraulic system and uses it for subsequent travel movements. This significantly reduces energy consumption without compromising the dynamics or precision of the proven single-mass system.

This allows you to save up to 30% of total energy consumption – an investment that is also eligible for funding.

PRECISE DYNAMICS

The four hydraulically driven lantern wheels of the forging machine enable high acceleration and delay-free reactions. The lantern wheels provide the feed, while separate running wheels carry the load. High positioning accuracy is achieved through form-fit power transmission and mutual bracing of the lantern wheels.

The externally mounted lantern racks also ensure good accessibility for maintenance and service. This reduces maintenance effort and costs while increasing operating comfort. In addition, the all-wheel drive helps minimize wear, extend maintenance intervals, and reduce your long-term operating costs.

In addition, the even load distribution across the rails guarantees stable handling even with workpieces weighing several hundred tons, ensuring process reliability and avoiding production interruptions.

7 ACTUATING AXES

- Moving forward/backward

- Parallel lifting/lowering

- Rotation of the tongs left/right

- Tilting (incline) up/down

- Parallel side shift left/right

- Lateral swivel left/right

- Opening/closing the tongs

PRECISION*

- Moving forward/backward: ± 1.5~4 mm

- Rotation of the tongs: ≤ ± 0.3°

- Parallel lifting/lowering: ± 1~3 mm

*depending on the size of the manipulator

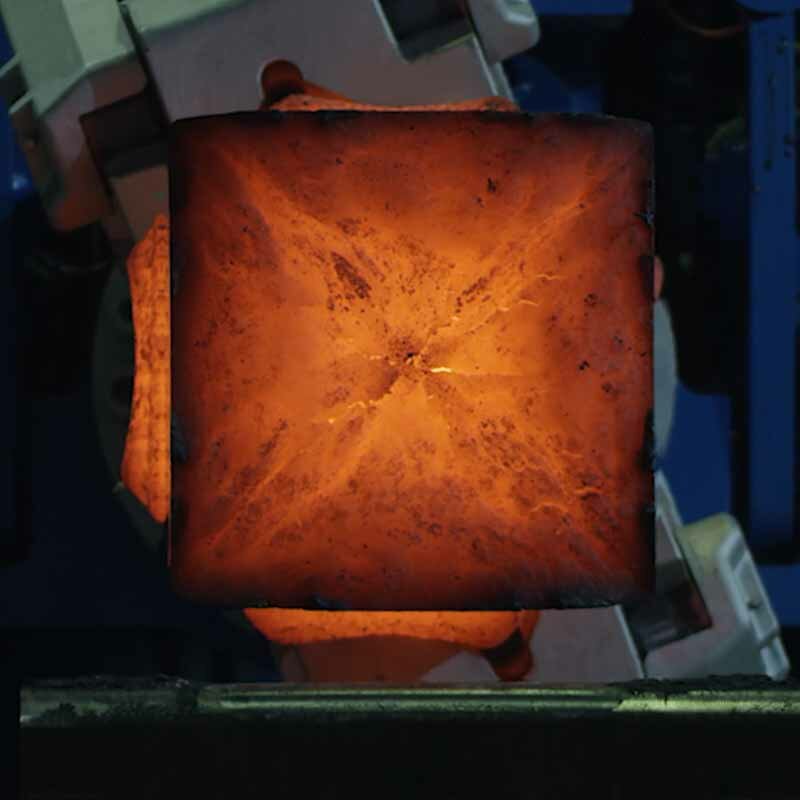

Block tongs

- Large gripping diameter despite compact design

- Adaptation of the gripping range through exchangeable jaws

Disk pliers

- Block tongs can be converted to disk tongs

- Extended gripping range for forging disks and rings, as well as upsetting

TANDEM FORGING

Forging lines achieve their maximum productivity when two manipulators work together in synchronized tandem operation. Especially with long or heavy forgings, the interaction prevents bending, eliminating the need for subsequent straightening.

The systems can be configured flexibly: rail-bound and mobile manipulators can be combined with each other as desired. A second manipulator replaces the imprecise chain and enables precise “hand-in-hand” forging of both ends.

Integrated operation with connection to the press control system is one of the particular strengths of our systems. The automation has already been successfully implemented with presses from various well-known manufacturers and has proven itself in operation.

SAFETY FIRST

The rail-mounted forging manipulator is equipped with a dedicated safety control system: during machine setup and maintenance, the motion axes are operated via a compact wireless remote control, the so-called “enabling switch”. As soon as this control device is removed from its holder on the forging machine, all other controls are blocked and the reduced setup speed is activated.

The result: High safety for both service personnel and people in the surrounding area.

The space between the press and the manipulator is also protected by a safety fence. Where this is not possible, the forging manipulator can be optionally equipped with laser scanners: if there is an object in the rear area, the drive stops automatically.

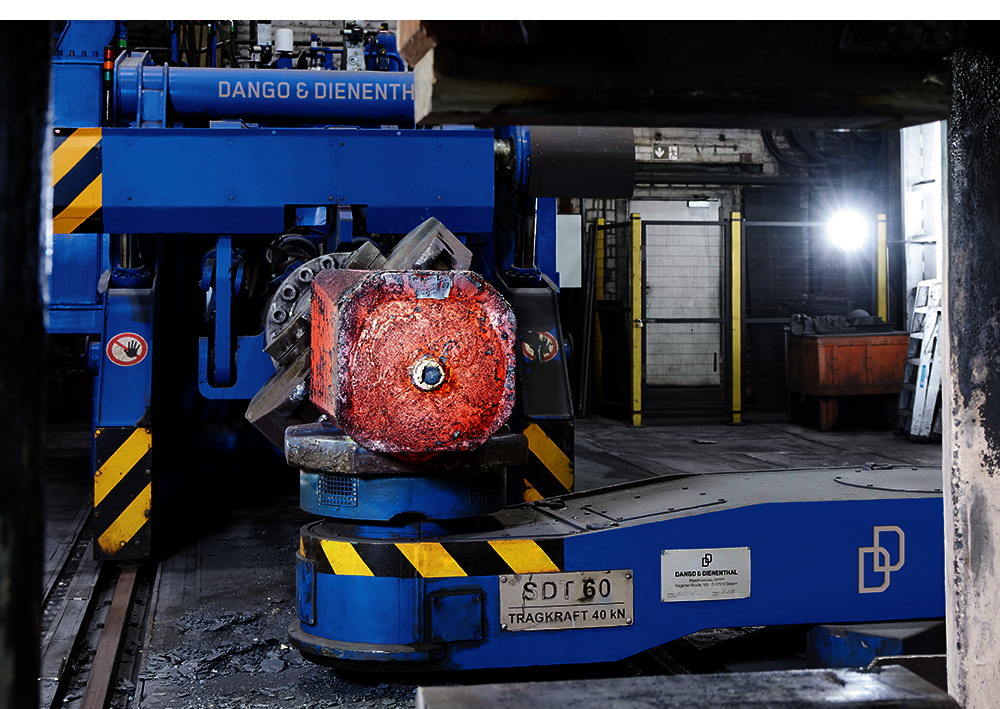

Turntables for

Open-die forging

With our turntables, you optimize your production workflows: short handling times, fast alignment of workpieces, and smooth transfer to the manipulator accelerate the overall process. At the same time, high crane availability and increased work safety ensure efficient and safe working in your production hall.

MOVABLE

When a workpiece is delivered crosswise to the manipulator, the turntable moves into the travel path of the forging manipulator, rotates it, and moves back to its parked position.

SWIVELING

The table is installed to the side of the press and is pivoted into the travel path of the forging manipulator, and back out again later.

LOWERABLE

The pop-up turntable is recessed into the floor of the forging shop. It is raised when needed and then lowered again.

IN GOOD HANDS

More Service

Downloads

CONTACT US

Are you interested in our product?

Then contact us via the contact form, contactnoSpam@dango-dienenthalnoSpam.de or +49 271 401 4000.

We look forward to your inquiry!